The Marion Power Shovel Company in Marion, Ohio, in 1965 built the world’s largest land vehicle, NASA’s Crawler Transporter (CT). It played a key role in the Apollo program, which landed Americans on the moon, and then tackled a new mission to help launch the space shuttle fleet. Bucyrus International acquired the Marion Power Shovel Company in 1997.

How do you move 12 million pounds worth of a Saturn V rocket and its launching derrick 5 miles from an assembly building to the launch pad? Oh, by the way, you’ve got to keep the rocket vertical while negotiating a road with grades of 5 degrees.

NASA faced that problem in the 1960s, as the Apollo program swung into full gear. The Saturn V rocket had to be enormous to lift the 45-ton Apollo spacecraft on those historic earth orbital and lunar missions from 1967 to 1972. Engineers would assemble the rocket in a vehicle-assembly building located about 5 miles from the launch pad.

For the answer, NASA turned to Marion, a company world famous since the late 1800s for building mammoth steam shovels and other machines for digging and earth moving. The Ohio company built two identical machines straight out of science fiction. The Crawler Transporter is 131 feet long, 114 feet wide, weighs 6 million pounds, and rides on 4 double tracks, each pair bigger than a school bus. Its two giant diesel engines crank out 8,000 horsepower. They drive electric generators that supply current for the vehicle’s 16 electric motors, which move it at a top speed of 1-2 miles per hour.

Fuel economy? About 42 feet per gallon, or 126 gallons per mile.

The Crawler Transporter, however, is both brawn and brains, with a sophisticated automatic load-leveling system that keeps spacecraft level, despite slight dips in the road.

Marion built the behemoths in Ohio, and shipped them to the Kennedy Space Center (KSC) in Florida for assembly. The Crawler Transporters carried all of the Apollo program rockets to the launch pad, including Apollo 11, the first lunar landing mission in 1969. Then they were modified for service in the space shuttle program.

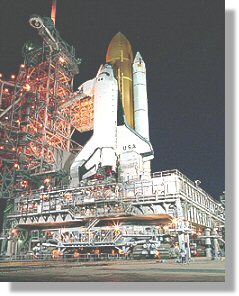

KSC workers assemble the airplane-like shuttle orbiter, external fuel tank, and solid rocket boosters inside a huge building. Then the CT lifts the vehicle and its mobile launcher, and carries it to the launch pad. The upgraded Crawler Transporters use a laser guidance system to reach the launch pad, where they PLACE the Shuttle-topped mobile launcher onto the pad pedestals. The CT then rumbles away to a secure parking site away from the pad to avoid possible damage from launch.

If hurricane-strength winds move in, NASA summons a CT to carry the shuttle back to the safety of the vehicle assembly building. That return trip also may be necessary to repair problems with the shuttle detected just before launch. After each launch, the Crawler Transporter removes the mobile launcher from the pad so it can be refurbished.

Find out more...