Michael J. Owens in 1903 invented the first commercially successful, fully automatic bottle-making machine in 1903 in Toledo, then a world glass manufacturing center. The machine could produce 13,000 bottles a day and made glass containers cheap enough for foods, beverages, and other household products. It also ended child labor in the glass industry, since teams of young boys had been employed to make glass bottles by hand, and helped to establish Toledo as "the Glass Capital of the World."

Owens came from a hard working family. His father was a coal miner, and he himself began working at the early age of ten in a glass factory in Wheeling, WV. He knew all too well the hardships of a small child working in the heat and rough environment of glass furnaces. Over the next twenty years, he moved up through the factory and ultimately became a skilled glassblower.

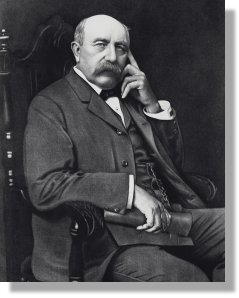

In 1888 he moved to Toledo, OH and began a glassblowing career at Libbey. There he developed a bottle machine that automated the bottle making process and virtually eliminated child labor in the glass industry. The project was financed by Edward D. Libbey (1854-1925) and executed with the aid of engineers William Boch, C. William Schwenzfeier, and Richard LaFrance. Through automating the glass blowing process, glass bottles and jars became less expensive to produce and were used for more and more applications.

Owens Community College in Toledo, Ohio is also named after Michael Owens. He is also the "Owens" in Owens-Illinois, Owens Corning and Libbey-Owens-Ford.

Find out more...